Liquid Metal: The Future of Automotive Cooling Systems

In the world of automotive engineering, a revolution is quietly brewing beneath the hood. Liquid metal cooling systems are emerging as a game-changing technology, promising to redefine thermal management in vehicles. This cutting-edge approach combines the efficiency of liquid cooling with the thermal conductivity of metals, offering a solution that could dramatically enhance engine performance, fuel efficiency, and overall vehicle design. As we delve into this exciting development, we'll explore how liquid metal cooling systems work, their potential benefits, and the challenges that lie ahead in bringing this technology to the mainstream automotive market.

Enter liquid metal cooling systems. These innovative solutions leverage the unique properties of liquid metals, such as gallium alloys, to revolutionize heat management in vehicles. With thermal conductivities several times higher than water or conventional coolants, liquid metals can transfer heat more efficiently, potentially leading to smaller, more compact cooling systems and improved overall engine efficiency.

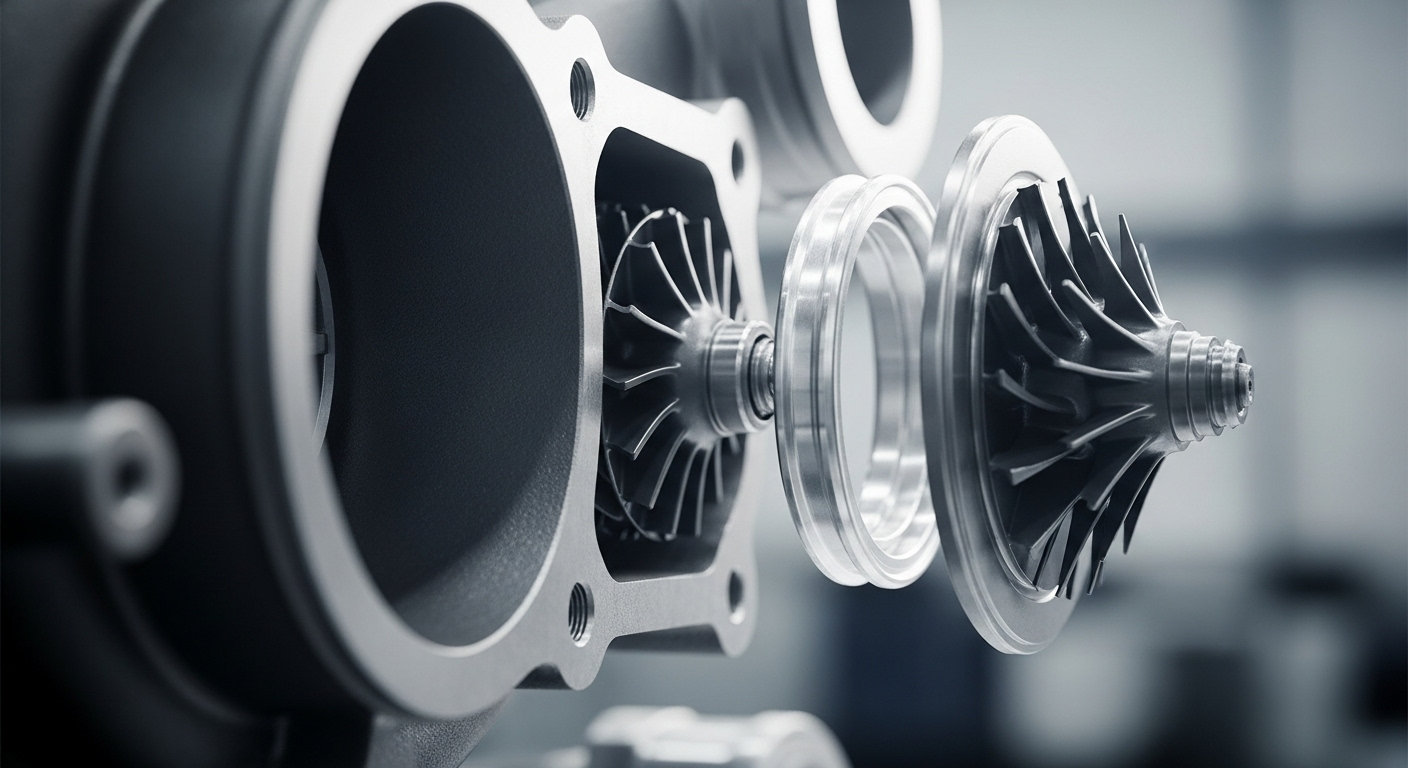

The Science Behind Liquid Metal Cooling

At the heart of liquid metal cooling systems lies a fascinating interplay of physics and chemistry. Unlike traditional coolants, which rely on convection to transfer heat, liquid metals can conduct heat directly. This property allows for rapid and efficient heat dissipation from engine components.

Gallium alloys, in particular, have garnered attention for their low melting points and high boiling points, making them ideal for automotive applications. These alloys remain liquid at room temperature, eliminating the need for pressurized systems and reducing the risk of freezing in cold climates. Moreover, their ability to conform to complex shapes and flow through narrow channels opens up new possibilities in engine design and thermal management.

Reimagining Engine Design

The adoption of liquid metal cooling systems could lead to a fundamental rethink of engine architecture. With more efficient heat transfer, engines could be designed to run at higher temperatures, potentially increasing power output and fuel efficiency. The compact nature of liquid metal cooling systems could also allow for sleeker, more aerodynamic vehicle designs by reducing the size of radiators and simplifying cooling system layouts.

Furthermore, the ability of liquid metals to cool specific components more effectively could enable the use of lighter materials in engine construction. Parts that were previously required to be made from heat-resistant alloys could potentially be manufactured from lighter materials, contributing to overall vehicle weight reduction and improved fuel economy.

Beyond the Engine: Wider Applications

While the primary focus of liquid metal cooling systems has been on engine thermal management, the technology holds promise for other automotive applications as well. High-performance braking systems, which generate significant heat during operation, could benefit from the enhanced cooling capabilities of liquid metals. Electric vehicle batteries, which require precise temperature control for optimal performance and longevity, represent another potential application area.

In the realm of motorsports, where every fraction of a second counts, liquid metal cooling systems could provide a competitive edge. The ability to maintain optimal operating temperatures under extreme conditions could translate into improved reliability and performance on the track.

Challenges and Considerations

Despite the promising potential of liquid metal cooling systems, several challenges must be addressed before widespread adoption becomes feasible. One primary concern is the compatibility of liquid metals with other materials used in engine construction. Gallium alloys, for instance, can be corrosive to certain metals, necessitating careful material selection and system design.

Safety considerations also come into play. While gallium alloys are generally considered non-toxic, proper containment and handling procedures must be developed to prevent leaks or spills. Additionally, the higher cost of liquid metals compared to traditional coolants may initially limit their adoption to high-end or performance vehicles.

The Road Ahead: From Concept to Reality

As with any emerging technology, the path from laboratory to production line is fraught with challenges. Extensive testing and refinement will be necessary to ensure the reliability and durability of liquid metal cooling systems under real-world conditions. Collaboration between automotive manufacturers, materials scientists, and thermal management experts will be crucial in overcoming technical hurdles and developing standardized solutions.

However, the potential benefits of liquid metal cooling systems make them a compelling area of research and development. As environmental regulations become increasingly stringent and consumers demand more efficient vehicles, innovations in thermal management will play a critical role in shaping the future of automotive engineering.

In conclusion, liquid metal cooling systems represent a fascinating convergence of materials science and automotive engineering. While challenges remain, the technology offers a tantalizing glimpse into a future where vehicles are not only more powerful and efficient but also more elegantly designed. As research progresses and hurdles are overcome, we may soon see liquid metal cooling systems emerge as a standard feature in the vehicles of tomorrow, ushering in a new era of automotive thermal management.